Why you no longer need to program robots

Previously, robots were mainly applied in serial production, such as automotive and electronics, due to the complexity of programming. ABAGY brings the efficiency of a conveyor line to non-serial, high-mix production.

We provide autonomous welding. You can easily switch from one product to another. Just a few clicks, no programming.

We install our software, which automatically generates the robot path in minutes, as well as hardware, which includes machine vision and ABAGY Box.

ABAGY WELD: SOFTWARE FEATURES

No programming

Any product mix

Any robotic equipment

Any deviations

With the traditional approach, the programmer needs to program each point of the robot's trajectory, taking into account the position of the part and its fixtures, and synchronizing all the equipment with each other. It usually takes hours, days, or even weeks for every part.

With ABAGY, you only need 10 minutes to set a robot task for a brand-new product. Upload a 3D model of your product (in any CAD format) and set the welding parameters you need. The rest will be done automatically.

Automatic detection and avoidance of clamps and fixtures

03

No "zero points" placement is required. Loading your workpieces doesn’t need to be precise

04

Automatic detection of part deviations

02

Ease of switching from one product to another. Hundreds of different parts in a single cell

01

Supports different weld joints and parameters

01

Makes the input of welding parameters easy: enter only once and those selections are saved

02

Forms your own welding procedures library

03

Various machine vision systems (from the more expensive to the more affordable ones, depending on your needs)

04

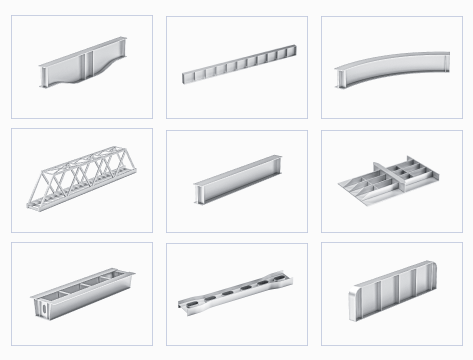

Different robotic systems (gantries, positioners, etc.; any number of axes)

03

Major welding power source manufacturers

02

Major robot manufacturers

01

Multiple robots working together in a single workspace

05

Abagy is compatible with:

User-friendly interface. You are only a couple of hours away from mastering it

Real-time processes in a cell

Full statistics about all processes

Automation of maintenance, including automatic system recovery

01

02

03

04

SOFTWARE INTERFACE

Welding parameters

You don't have to worry about HOW the robots will perform the task. You only need to decide WHAT they need to weld. The system automatically recognizes all welds on the part’s 3D model. You define the welding order and parameters.

The digital twin of your cell

Before actual welding, you can watch a welding simulation. The system will generate it automatically.

Scanning the part

With the help of machine vision, we recognize fixtures or possible part deviations and adapt the robot path on the fly.

Watch the video Excavator Bucket Welding

ABAGY HARDWARE

01

02

Using machine vision, ABAGY’s system "sees" the part, the fixtures or clamps, and knows their positions. Reference points are not required. The system automatically recognizes part variations and adjusts the robot's path on the fly.

MACHINE VISION

No risk of hacking. ABAGY's LAN is an isolated network that only provides access to the equipment installed inside the robotic cell.

ABAGY BOX

We offer two options: installing a new robotic cell or retrofitting your current one. In the second option, additional hardware is typically just the machine vision and ABAGY box (server). You can be up and running in just a few days after setup.

Why is robot programming such a big problem?

In the traditional approach, there are several ways to program robots. Learn how they work and compare how they differ from ABAGY.

Why is it still challenging to program cobots as well?

Robotic Welding. How to know if robots are right for your production